LED Made Easy - Eliminate the Repairs and Bulb Changes on Your Old Lighting System

December 17, 2017

Stop making expensive repairs, bulb changes and move to a new, best-in- class, LED tower lighting system with NO UPFRONT COSTS.

The Opportunity

If you are still operating your tower’s obstruction lighting system with incandescent or xenon technology, you are missing out on a unique opportunity to reduce costs, eliminate the hassle of lighting system repairs, bulb changes and maintenance. Tower Lighting as a Service℠ (TLaaS℠) presents a unique opportunity to lower your annual cost for lighting and gain the benefits of LED technology. Even more amazing is the fact that you can purchase and own your system at the end of the contract term and there is No Upfront Cost on your part. Here are the details:

Maintenance Cost Summary on Legacy Systems

Cost of light bulb replacement:

The FCC requires that lit structures remain lit, but depending upon the type of lighting system and bulb, the life of that bulb will vary. If a light bulb goes out, then that light bulb must be changed.

There are three cost drivers here:

- Bulb Lifespan – All bulbs having varying degrees of life and cost. An incandescent light might have a life of 8,000 hours or almost a year, perhaps more, perhaps less. A xenon bulb might have a life of 20,000 hours or 2.28 years, with some variance. LED’s are in a whole different class with a lifespan estimates 10-20 times greater than the older technologies.

- Bulb Cost - Legacy bulb costs depend on type and technology with costs ranging from $75 to over $1,000 for the bulb, excluding installation.

- Tower Crew Labor to Replace Bulb – The key drivers are tower height, type of lighting system, labor hours and mobilization. Costs can range anywhere from $1,200 to more than $5,000 per bulb change.

Lighting System Repair and Maintenance:

Lighting systems have electronic components that fail, just like any computer, router or switch. This equipment may also include legacy monitoring equipment. Many times, the lighting system components are older technology with poor MTBF profiles and elevated active components that require tower climbs for repairs. This coupled with the often-harsh conditions results in high failure rates. Should a power supply, controller board, capacitor, trigger board, or any other component, or perhaps the entire controller system fail, the item must be repaired.

There are two potential cost impacts with this requirement:

- Equipment Cost - The costs range greatly depending on the nature of the issue and the type of system you have. Component costs vary from a few hundred dollars to thousands.

- Technician or Tower Crew to Replace Hardware – The same factors apply here as to a full lighting system installation including where the equipment is located (up on the tower or down in shelter), type of lighting system, labor hours and mobilization. Costs can range anywhere from $500 to over $5,000.

Electricity

– LED’s use ~90% less electricity than outdated legacy systems. Depending on your FAA tower styleand your local utility’s electricity cost…. this can be a significant savings over the life of the system.

Your Team’s Time

– The cost of your time dealing with legacy systems can be significant including: NOTAM management, finding a reliable repair team, ensuring they have proper insurance, managing safety status and certifications, ordering equipment and bulbs, shipping receiving and kitting of equipment, project management, quality control and assurance, closeout package review and more. Tower owners spend significant time and money just managing all the problems that occur with legacy lighting systems.

TLaaS℠ - A New Option to Upgrade Your System

One new and unique option to eliminate the cost of these repairs is TLaaS℠

- a proprietary solution offered by LumenServe℠. TLaaS℠ includes:

- Draft FAA Required Paperwork for Lighting Change - Draft all the required FAA form filings, from documentation through submission, including. process approval, new installations, advanced notifications, and compliance.

- Installation of New LED Lighting System - Certified installation of the best LED obstruction lighting systems available pursuant to manufacturer's specifications to ensure full warranty compliance.

- Decommission of Old Lighting System - Decommission and remove the old lighting system, including old lighting fixtures, electronics, and cabling. All decommissioned equipment and materials are properly disposed of.

- Installation Close Out Package Documentation - Photo documentation of the entire system is provided to tower owners in a professional close out package.

The Bottom Line

TLaaS℠ is provided with no upfront cost, a flat monthly payment over the term (typically ~60 months), and the option to purchase the LED system for $1 at the end. It includes an Assurance Warranty

which provides for all parts and labor to ensure the system is functioning properly. Compliance and monitoring

and FAA required Tower Inspection Services

are available options.

Legacy System Costs: > TLaaS℠

Bulb Changes ($0 upfront, flat $/month, $1 buyout)

System Repairs & Component Replacements

Technician & Climber Labor

Electricity At Higher Cost

Your Team's Time

LumenServe℠

can help you analyze the costs and benefits of all your options. Also, don’t forget, as the nation’s first Tower Lighting as a Service℠ company, LumenServe℠ can provide qualified customers with a lighting solution that requires no upfront costs. Let us look at your situation and see if we can help you.

For more information or quote, please contact LumenServe℠ at:

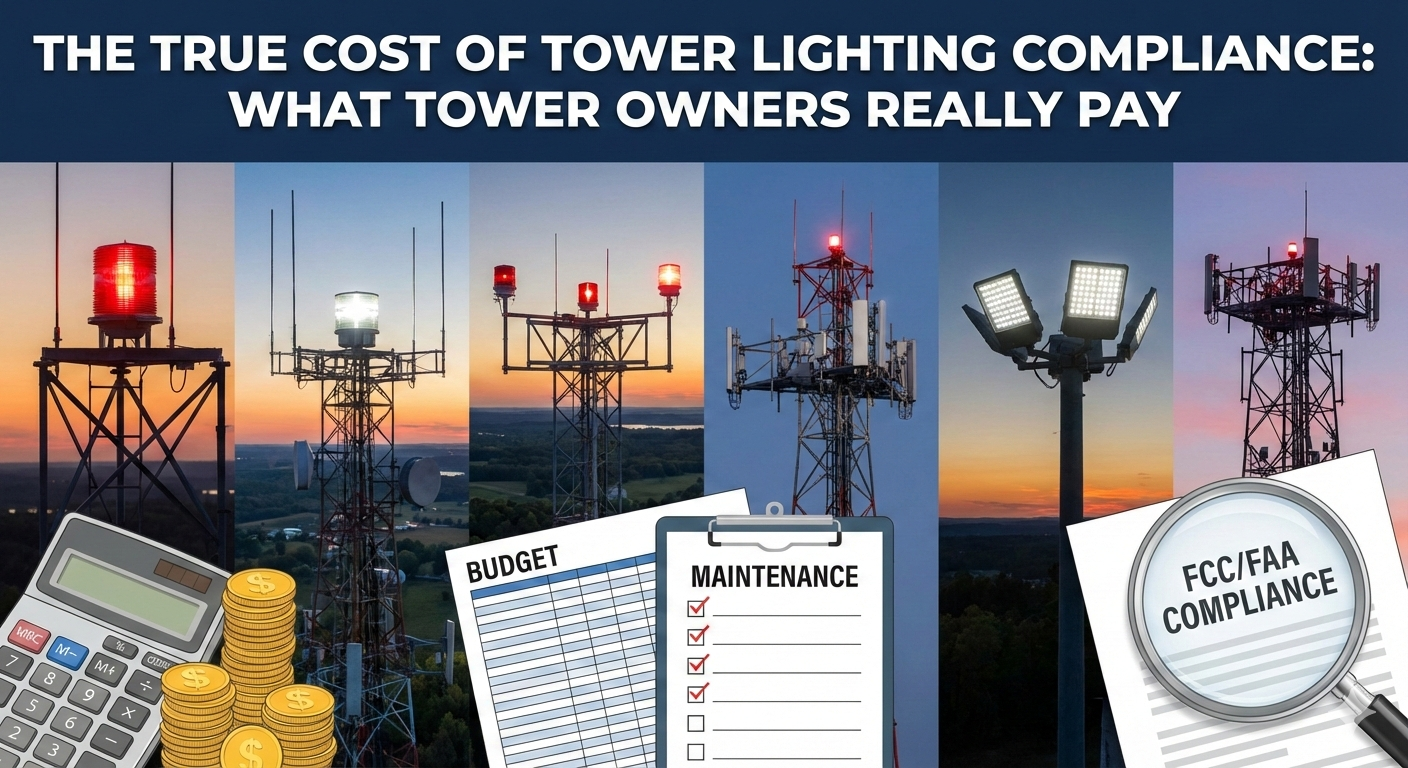

In this installment of our YouTube video series review, we'll cover the actual costs of ensuring your tower is lit correctly. Tower lighting is a critical part of aviation safety and federal compliance, but the true cost of tower ownership extends far beyond the obvious price of the lights themselves. To illustrate this, let’s break down the real monthly cost of operating a 300-foot painted FAA medium-intensity A1 tower using a legacy incandescent lighting system. To keep the analysis practical and budget-friendly, all costs are expressed on a monthly basis, which reflects how most operators track operational spending. Hard Costs: The Direct, Visible Expenses These are the line items that appear on invoices and budgets. 1. Lighting System Reserve • System purchase & installation: $17,980 • Depreciation: 12 years • Monthly cost: $125 2. Tower Painting Reserve • 300 ft painted tower • Cost: $40 per linear foot • Paint life: 7 years • Monthly cost: $140 3. Repairs & Compliance Documentation • One repair per year: $1,900 (parts + tower climb) • FAA paint card inspection & documentation: $233 annually • Monthly cost: $178 4. Quarterly On-Site Inspections • Required for compliance • Monthly cost: $89 5. Electrical Power • Legacy incandescent system • Average commercial electricity rates • Monthly cost: $60 6. Compliance Monitoring & Data • Monitoring unit installed: $1,900 • Depreciated over 7 years • Monthly service fee: $30 • Secure data plan: $10 • Monthly cost: $72 Total Hard Costs: $667 per Month This equals $8,004 per year for a single medium-intensity painted tower. Soft Costs: The Hidden Operational Burden Soft costs don’t show up on invoices, but they consume time, staff, and internal resources: • Coordinating tower climbs and repairs • Managing vendor schedules and contracts • Procurement and logistics • Site access and safety coordination • Documentation and recordkeeping • Internal compliance management These administrative burdens quietly inflate the real cost of tower ownership. Risk Costs: The Unpredictable Financial Exposure Even well-managed towers face uncontrollable risks: • Inflation: Rising labor, parts, and energy costs • Compliance risk: Missed inspections or documentation gaps • Capital shocks: Sudden lighting system replacements • Catastrophic events: Storm damage, equipment failures, accidents These risks can rapidly exceed annual budgets and disrupt operations. The Bottom Line: Ownership Is More Expensive Than It Looks Hard costs alone average $8,000 per year for a single FAA A1 medium-intensity painted tower. Once soft costs and risk exposure are included, the true financial burden is significantly higher. There Is a Smarter Way There is another model that can reduce your tower lighting costs by up to 50% while eliminating risk, compliance stress, and operational complexity. To learn more, explore our solution series or visit LumenServe.com to see how Tower Lighting as a Service® changes the economics of compliance. For more compliance guidance, check out our other educational series blog posts: 1. Tower Lighting Compliance Checklist: How to Stay FAA & FCC Compliant 2. What is a NOTAM? 3. Tower Lighting Inspections: FCC & FAA Requirements Every Tower Owner Must Know 4. Why Some Towers Rely on Paint Instead of Lights

Ever wonder why some towers are painted red (or aviation orange) and others are not? Here is part 4 of our educational YouTube series that helps you learn all about it! Not all towers use lighting systems for daytime visibility. Towers marked with alternating bands of aviation orange and white are classified under FAA Style A marking. Instead of relying on lights, these structures depend on high-contrast paint to remain visible to aircraft during daylight hours. Maintaining this marking is not optional, it is a federal requirement. What the FAA Requires According to FAA Advisory Circular AC 70/7460-1: “Antenna structures requiring painting shall be cleaned or repainted as often as necessary to maintain good visibility.” To determine whether a tower remains compliant, owners must evaluate the paint condition using the FAA In-Service Aviation Orange Tolerance Chart. Why Paint Fails Over Time Environmental exposure gradually degrades tower paint: • UV radiation • Wind abrasion • Rain and weather extremes This causes fading, which reduces contrast and aviation visibility. Once faded beyond tolerance limits, the tower is no longer compliant and must be repainted or cleaned.

We extend our condolences to the families impacted by the recent helicopter crash in Houston’s Second Ward. While the cause is still under investigation, this tragedy is a reminder of how crucial obstruction lighting is for aviation safety. At LumenServe ℠ , we are dedicated to delivering innovative solutions that ensure your towers meet federal compliance standards, operate at peak efficiency, and ultimately protect lives. With cutting-edge technology, including Infrared (IR)-capable LED lighting systems, we help you stay ahead in safety and compliance without compromising on quality or cost.

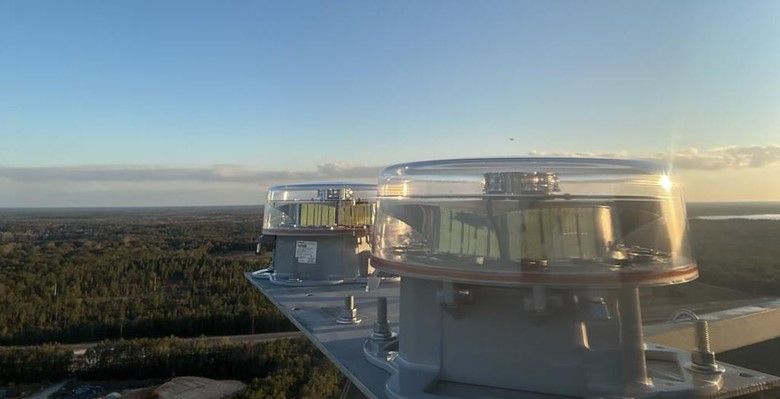

Effective as of September 11, 2020, the FAA requires Infrared Emitters (IR) for your LED obstruction lighting for newly constructed towers or circular updates. The FAA’s Advisory Circular (AC) spells out the specifications for IR and obstruction lighting equipment. The obstruction lighting rules were created in response to the Safety Risk Assessment of LEDs in Aircraft Operations with the FAA establishing IR specifications for LED based obstruction lights. Specifications are contained in Airport Engineering Brief 98 and Infrared Specifications for Aviation Obstruction Light Compatibility with Night Vision Goggles, published December 18, 2017. Military, emergency service, and other helicopter pilots are starting to use NVGs more frequently for increased safety and to amplify visible light. The illustrations below highlight the need for IR with your obstruction lighting.

Simplify Your Tower Lighting Compliance with LumenServe℠ Attention tower owners! Staying on top of federally mandated lighting compliance regulations is crucial, but it doesn't have to be overwhelming. LumenServe℠ is here to help with our all-inclusive program that takes the stress out of compliance and monitoring. Are You Up to Date with FAA Regulations? Here's a straightforward compliance checklist: Monitor Your Lighting Systems: If there's an unresolved qualifying outage, file a Notice to Air Mission (NOTAM) with the FAA within 30 minutes, and clear the NOTAM once resolved. Daily Monitoring Logs: Create and maintain compliance logs for at least two years. Quarterly On-Site Inspections: Ensure your lighting systems are functioning correctly. Paint Inspections: Check the top portion of Style A towers. Biennial Lens Inspections: Regularly inspect your lenses every two years. Stay Ahead with New Regulations Regulations are always evolving. Whether it's the 7/8ths inch rule, IR lighting specifications, or the Avian standard, staying compliant can be a challenge. But that's where LumenServe℠ comes in! LumenServe℠ offers a complete range of compliance services to make your life easier: Compliance & Monitoring Services 24/7/365 Active Monitoring: Continuous monitoring of your lighting system. Remote Diagnostics: Quickly identify and resolve issues. FAA NOTAM Management: Reporting, tracking, and resolution. Daily Logs: Maintain logs with over two years of storage. Lighting Circular Validation FAA Rule Updates: Stay informed on new rules like the 7/8ths inch rule, IR LEDs, and aviation lighting regulations. Customer Reports: Stay in the loop with everything regarding your tower lighting. On-Site Tower Lighting Inspections Quarterly Lighting Inspections: Regular checks to ensure proper operation. Biennial Lens Inspections: Comprehensive lens checks every two years. Paint Inspections: For the top portion of Style A towers. Real-Time Monitoring and Updates With our 24/7/365 Network Operations Centers and customer portal, you'll always be informed about your tower’s health, alarm status, maintenance, and repair history. Trust LumenServe℠ for Compliance Rely on us to keep your tower compliant. Our expertise and scale can save you money and free up your time to focus on your core business. Contact LumenServe℠ today to learn more about our services. Contact Us Phone: (512) 580-4600 Email: info@LumenServe.com

Tower owners with FAA Style A marking, which includes painted towers with red obstruction lighting at night, should be aware that there are cost-saving options to consider when it comes to periodic painting required for compliance. Here at LumenServe ℠ , our Never Paint Your Tower A gain program eliminates the need to repaint your tower for obstruction lighting purposes. First, let us clarify some background information. Painting of the structure: FAA Style A towers are painted to ensure visibility for air navigation, with specific requirements for painting the structure. The most important requirement is that the paint must meet the FAA's Aviation Orange color standard, which is Federal Standard 595 color #17875 for white and color #12197 for aviation orange. Additionally, the number of bands required on the tower depends on its height. You can visit our website for helpful information on each FAA Tower Style. Cost of painting of the structure: When evaluating the cost of painting a structure, there are five primary cost drivers: Material cost of paint – Paint costs approximately $70 per gallon with each gallon covering roughly 400 sq. ft. Tower type – There are three primary tower types - Guyed, Self-Supported, or Monopole. Each tower type is unique and requires a different amount of labor to complete depending on total surface area and other factors. Height of tower – As one would expect, the height of the tower is directly proportional to the amount of labor required to do the painting. Tower location – Tower crews charge to mobilize to the site. The more difficult it is to get to the location, the more the tower crew will charge to get there. Tower crew labor cost – The labor cost to paint your tower is typically based on the hours of work required for the project. Typically, labor will range from $25 per tower foot to $80 per tower foot depending on tower type, height, and location. Annual paint test:

In the world of tower maintenance, costs can soar to new heights, especially when it comes to climbs. Picture this: a typical climb on a 325’ tower can set you back a staggering $2,500 each time – a price that quickly accumulates with multiple climbs over the life of your lighting system. Now, what if we told you that there's a smarter, more cost-effective way to safeguard your tower's lighting without breaking the bank? Enter our fully comprehensive Assurance Warranty Service , an unbeatable solution that not only saves you money but offers peace of mind like never before. With an annual cost that is less than ½ of the cost a single tower climb referenced above, you'll receive not only all the tower climbs necessary to support your lighting system, but a level of support that covers everything from diagnostics to repairs, equipment replacements, mobilization and more. Our Assurance Warranty Service is only available with newly purchased and installed systems through LumenServe or through our Tower Lighting as a Service ® solution. Our Assurance Warranty Service is designed to be a game-changer in tower lighting maintenance. It covers the full array of services need to keep your system operational and in full compliance including: Problem diagnosis Remote troubleshooting Equipment replacement Site mobilization and expenses Repair labor on the ground Tower climb labor Shipping and transport RMA (Return Merchandise Authorization) Firmware upgrades All associated expenses In essence, it's your one-stop solution for ensuring the proper operation of your tower lighting system. Here are some more details on our Assurance Warranty Service . The math is simple: when you opt for the LumenServe℠ solutions that includes our Assurance Warranty, you're not just saving money; you're investing in long-term reliability and peace of mind. Say goodbye to the anxiety of unpredictable costs associated with tower climbs and embrace a more cost-effective and comprehensive approach to tower lighting maintenance. Join us on a journey where you can "Scale Heights, Not Costs," and let your tower shine brighter than ever before. For more information, please contact LumenServe℠ today!